By Amanda Figueras

Investment is somehow one of the most controversial aspects in companies’ lives. Through in-vestments, companies are expanding something tangible without quite knowing what the result will be, trying to make an educated bet, with the hope of eventually collecting a payout. But how much will a company receive in return, and when?

For most, digital technology represents a quintessential mystery in terms of investments to be made. In the context of the oil and gas industry, the challenge for decision makers becomes in-creasingly difficult due to the pressing characteristics of this results-driven environment. Is the industry on the right path in the midst of the information revolution? Which digital technology is ripe for investments, and which one is on the way out? How can one assess what each course of action is worth? How can one measure its potential impact?

For years, investments in information technology within the oil and gas industry have lagged be-hind. While the delay has not be as evident as in other industries, an acute lack of investment in this segment has resulted in weak Information Technology (IT) departments, as Chief Information Executives (CIOs) are struggling to keep up with the business horizon increasingly revolutionized by the latest digital advances. Fortune favors the bold. However, there are few industries where this classical dictum materializes. Companies that have yet to adapt to new technological advanc-es are those that are suffering the most today, weighed down by outdated work methods. For when it comes to digital technology, one is not talking about future aspirations, but rather about urgent demands of the present.

Digital Technology Is Essential

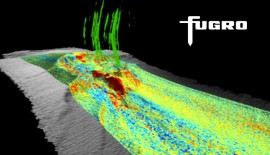

Digital technologies – in addition to seismic imaging – have the potential to make radical changes to how energy resources are found, extracted, and used, providing opportunities for more efficient operations through unparalleled levels of data analysis. As BP stated in its Technology Outlook Report released in November 2015 regarding the oil and gas industry, sensor technologies in equipment such as pumps, wells, and appliances are increasingly being employed by leading play-ers in the field.

“When connected to data collection mechanisms, they provide real-time information on field ac-tivities. Intelligent wells – providing updates on well condition from top to bottom – are now be-coming a reality, a development that reduces both non-productive time and cost,” the report stat-ed.

Together with the rapid development of data analytics and management techniques, the industry can find oil and gas resources faster and more effectively, while operating refineries and manu-facturing plants more efficiently. Therefore, digital technologies provide a road to a faster and better decision-making process, boost safety, productivity, and efficiency, which ultimately means considerable savings. Specifically, the BP study estimated that digital technologies have the po-tential to increase production volumes by 4% and reduce costs by 13% by 2050.

“Technology is likely to have the most impact on resources that are difficult to produce or those that are sparsely exploited today, such as ultra-deepwater and unconventionals. At a time of low-er prices, revenues, and capital spending, digital technologies – including sensors, data analytics, and automated systems – stand out as the leading contributors for reducing costs,” according to the report.

As Jarrod Bassan, a Senior Consultant at the Computer Sciences Corporation (CSC) – a global lead-er in providing technology enabled business solutions and services, with its headquarters in Ty-sons, Virginia, USA – explained in an email interview with Egypt Oil&Gas: “Operational efficiency is a key driver, and every initiative needs to show a return on investment in 6-12 months or less. Companies with a longer-term focus are investing now in piloting technology and new ways of working to drive efficiencies that make them hyper-competitive – both in terms of improved labor productivity and quality of work. Even when labor costs are low, the poor-quality work execution causes massive inefficiencies, unnecessary costs, and increased operational risk. Mature compa-nies understand this, and are working to dramatically improve the quality of work and productivity rates so they can reduce their operating costs.”

In this context, baseline technologies, but also new areas such as Outage Management Systems, Distribution Management Systems, and a wealth of other technology platforms are aimed at providing greater levels of insight, according to the experts from the CIO Energy Summit.

Digital Oil Field

A great example of the sort of technology directly applied to the so called digital oil field (DOF), which focuses on leveraging the benefits of modern IT, automation, and communications to en-hance all the conventional aspects of oil and gas operations, from exploration and production to environmental monitoring and safety, was recently highlighted by the Offshore Technology web-site.

More than just simply deploying digital and data management technologies, the DOF implies uni-fying disparate oil field processes into a more easily digestible stream of information, making it possible to get the big picture on an operation and thus optimize productivity in a real time, while minimizing the industry’s labor-intensive, hard-copy related hassle. “You can be seated here and do whatever you want there,” Douglas Brown, Project Superintendent for Offshore Operations at Oceaneering, told Egypt Oil&Gas in an interview.

Costly and risk-intensive deepwater wells are the ones that most require investing in modern in-formation technologies. It is undoubtedly becoming an increasingly worthwhile trade-off for safer, more efficient, and better-managed operations.

In this respect, the digitization of the oil industry has been ongoing for more than a decade, but industry CIOs say that the slump in oil prices has accelerated the process. Archana Deskus, Vice President and CIO for Baker Hughes, told CIO.com: “I definitely think the current downturn has caused us to start to look at doing things differently.”

Wearable Computing

Other technologies are becoming prominent in the industry. Brian Richards, Senior Manager and Energy Innovation Lead at Accenture bets on wearable computing such as head mounted devices, smart watches, and smart clothing. But how could this technology add value to the oil and gas industry?

According to analyses recently published by Accenture Energy Blog, there are three main ad-vantages.

First, wearable computing permits ‘shoulder coaching’, allowing a manager to see what a worker in a remote location sees, hear what he hears, and so forth. It is thus aiding in maintenance, training, safety issues etc. To put it in simple words, wearable computing helps oil and gas com-panies make better decisions faster.

Second, heads-up displays allow workers to process information in a real time as location infor-mation enables a manager to follow a process or procedure as they are actually being imple-mented.

Third, full-augmented reality allows the company to look at a piece of equipment, a dial or gauge, and overlay real-time information in order to make better decisions at a faster pace.

In Richards’ opinion, this technology “will change how field work is done, and represents the next evolution of mobility.”

Nevertheless, there is still a long way to go. One of the main challenges is that most of the devic-es on the market today are not intrinsically safe. Battery life is still limited, which raises even more questions.

Augmented Worker Technology

Accenture’s Senior Manager, Richards, is not alone in emphasizing the advantages of employing augmented reality (AR) that have been assessed for the mining industry, but can also apply for the oil and gas sector.

While more effective use of data combined with advanced analytics offers opportunities for im-provement, according to CSC, providing this information to the worker in the field in a real time has proven expensive, and cumbersome. New capabilities are therefore emerging, which address some of the limitations experienced to date. AR provides a means to overlay interactive digital information on top of the physical world.

“Augmented Worker technology allows video collaboration with remote experts, hands-free work instructions, and better condition monitoring of assets. For instance, this allows a remote worker to call up a remote maintenance expert, who can see a problem in a live video broadcast. This can reduce fault diagnosis, shorten diagnosing time, which in many cases means that the expert does not have to actually go out in the field,” Senior Consultant, Bassan, said for Egypt Oil&Gas.

In a white paper about the use of AR in the mining industry, Jarrod Bassan, who co-authored the piece, added that the benefits would manifest themselves through “better maintenance out-comes, more effective training, better collaboration and knowledge transfer, and enhanced situa-tional awareness for improved safety.”

The expert states that applying AR would allow a mobile worker to ‘see’ all relevant information for a given task, as well as read the physical environment, exactly at the moment when he can make the greatest use of the data. “These methods have been proven to be more effective than traditional text-based work instructions. The worker can also capture photo, video, and even thermal imaging data to more accurately describe a problem in the field, which allows planners to make more informed decisions,” he concluded.

Demonstrating the Value

The advantages of digital technology seem to be clear, however, one of the challenges that CIOs of the oil and gas sector face in this respect is to demonstrate the value of this kind of investment within such a production-driven industry. Indeed, a study conducted by the consultancy firm Ernst & Young in 2014 made it evident to see that the energy industry leaders feel that their sugges-tions are less respected, in the oil and gas sector in particular. They have revealed that they were dissatisfied with their remit, ability to influence broader company strategy, and with prevalent perceptions about the role of the CIO within different companies.

In addition to this, the reputation of IT departments has been damaged in recent years because of their inability to deliver on the monetary gains promised in business case documents for IT pro-jects, according to Marco van Staden, an operations subject matter expert, oil, gas, and energy at Ajilon, an Australian consulting firm, cited by CIO.com. “This is especially apparent in the oil and gas industry where IT projects are compared to equipment improvement projects that deliver immediate benefits like increased production,” he was quoted as saying.

In his opinion, there are three steps to be made to achieve the objective. First, there needs for a better understanding of how production impacts the bottom line, and it is essential to select the business drivers in which IT can provide a substantial improvement. “Throughout operations, costs, particularly maintenance costs, are usually the main drivers in the oil and gas industry with product prices [being] the major uncontrollable variable,” van Staden said.

Second, it is necessary to analyze these impacts and identify opportunities –equipment opportuni-ties and process/system opportunities – where the organization can be more efficient. “The main area where IT can deliver value is with identifying and exploiting opportunities related to business processes and systems, such as operating rounds and routine maintenance planning,” added van Staden.

And last, but not least, it is crucial to construct a portfolio of initiatives where IT plans are plotted along two axes: ease of implementation and impact.

Productivity Transformation

As Brian Richards wrote on Accenture Energy Blog: “For the oil and gas industry, the last 10 years were more about production than cost. The next 10 years will be about implementing digital technology to drive significant cost efficiencies.”

Given current oil prices, which are below $50 per barrel, energy companies are battling amongst themselves in a hard-fought price war, aiming to prove that they are capable of producing oil and gas at the best price. It is essential to analyze the operating model from top to bottom, from scheduling to training to production surveillance. “Things that used to be sacred, such as keeping ‘data within our walls,’ are now on the table, and it is time to take it to the next level,” wrote Richards on Accenture Energy Blog.

In other words, the oil and gas industry is facing a new productivity transformation, where digital technologies are the key to help companies discover new ways to move towards increased effi-ciency. There is no doubt left that in digital technologies, the future is happening already now.