With well optimization being specified as a major step in the country’s path toward production increase and cost reduction, representatives from key industry players shared their successful stories in a workshop dedicated to “Impactful Exploration and Development.”

21st Century Egypt E&P

In her presentation, Rand Al-Obaidy, Senior Petroleum Engineer and North Africa BD Manager at Gaffney Cline & Associates (GCA), suggested several solutions for increased oil production in Egypt. Her approach was to first review already existing wells and then apply various methods and techniques to increase their productivity. Al-Obaidy discussed several successful cases in-depth, including reviving the Amal field in the Gulf of Suez (GOS).

Oil asset managers were encouraged by Al-Obaidy to “listen” to existing wells, emphasizing that reviewing and reinterpreting them is the first step to increased productivity. “If we do nothing, we will continue with the natural declining of the field and it will dry up. However, if we invest, we could actually increase our enhanced oil recovery (EOR),” she stated.

Al-Obaidy stressed the importance of initiating this process now, so as to benefit both from the recent increase in oil production and the current low production cost in Egypt. “I will be confidently saying from all the projects I have worked on that Egypt definitely sets in the lower [ranking] of the cost per barrel,” she said, adding that GCA benefits significantly from this.

Sour gas reserves, especially the ones at GOS, represent another potential to increase production in Egypt, Al-Obaidy stated. As a senior petroleum engineer, she described the existing facilities at GOS as world class “I am not just saying that myself, but I went with facilities engineers and they were really impressed,” she explained.

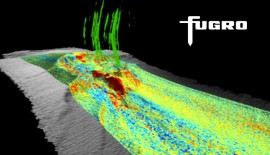

Regarding the challenges in well optimization, Al-Obaidy disclosed that the country faces imaging-related challenges, especially in the GOS. Yet, overcoming this problem is both rewarding and doable. “Recently, one of the clients we worked with reprocessed, reimaged and then reinterpreted the size that they have in GOS assets and, as a direct result from that, they are currently reviewing nine prospects – and of course this will be translated into more production,” Al-Obaidy explained.

Production from Yakout Shale

In a similar vein, the following presentation highlighted another aspect of the importance of re-exploring and re-studying already existing wells. Ahmed Essa, Geographical Operation Section Head of Agiba Petroleum Company, showed that reviving mature wells lead to uncovering new production opportunities.

Essa introduced the case of Agiba’s increased production in the Meleiha area through revisiting the Yakout Shale. He announced that, due to this recent study, the production of Agiba’s reservoir at Rosa North 4 in the Yakout Shale in Katatba will be stabilized at 3300 b/d.

The discovery of the Yakout shale formations in the Meleiha area and the increased production from the formation were another valuable example of exploration and production (E&P) improvement. When it was first tested, Agiba’s team overcame numerous challenges before initiating production from the shale, including the area’s porosity and seismic resolution, said Essa. “Measuring the seismic resolution to exactly detect the extension of the revoir was the main risk for us, because its seismic survey is very low.”

Essa summarized his presentation by emphasizing how the production from the Yakout Shale has been a turning point for Agiba and added that this specific case shows how even fields that are considered non-promising can increase production if restudied.

Unlocking Bypassed Oil

The third presentation was lead by Mostafa Mamdouh, Senior Reservoir Engineer at the Gulf of Suez Petroleum Company (GUPCO), who highlighted the importance of bypassed oil in mature fields. He also spoke highly of the productive value of combining engineering and geological data and discussed, cost reduction through rigless work. GUPCO’s development process carried out in the Belayim area was a perfect example of following these previously mentioned approaches.

“In such a high recovery factor of Belayim and such high performance reaching the red line of high water cap, it is not that easy to deliver new opportunities in that field,” Mamdouh said. He added that water injection in Belayim has been conducted for around 40 years, which reduced the field’s potential. Yet, positive results from GUPCO’s work at this field prove it is indeed possible to increase the productivity of mature reservoirs.

GUPCO’s team started operations at the southern part (B1) of Belayim, with lesser quality of sand, since it would be less affected by water injection. The team further tested three wells and managed to get 700 b/d from the first tested well, 500 b/d from the second, and 300 b/d from the third.

Mamdouh concluded his presentation stating that there is always a way to maximize oil productivity by following a robust integrated approach.