Digital transformation is moving towards rapid adoption of emerging technologies reshaping operations in the oil and gas space. End users are using technology approaches to improve productivity, enhance efficiency, and improve profitability. It is estimated that digital transformation can save as much as $1 trillion in operational spend over a period of 5 years. Companies that are accelerating deployment have a distinct edge in a dynamic and highly competitive industry landscape. Here are a few things to consider while mapping out the Digital Transformation approach in the oil and gas operating space.

Digital Transformation Roadmap – Assessment

The starting point of any digital transformation journey is understanding relative digital maturity, both within the organization and compared to industry peers. In fact, a crucial consideration has to be the different levels of digital maturity across different assets or workflows within the same operating company. It is important to note that it is not uncommon for various assets within the same operation to have different levels of digital adoption. Therefore, an initial assessment of digital readiness is imperative.

Technology partners such as Emerson engage with operating companies for a 360-degree assessment and benchmarking around digital maturity and create an indexing profile for end users. This profile scores maturity across key operational domains such as reliability, energy, environmental sustainability, production, safety, and security. Further, it combines operational, financial, and business data to align a comprehensive digital transformation approach with overall organizational goals such as sustainability and profitability.

Following this, specific roadmaps are developed for different domains considering infrastructure, resources, and capital availability to optimize the deployment process and investments.

Achieving horizontal and vertical scalability in terms of cost and technology integration right from Data acquisition to analytics.

As operators embark on the journey, a key area of focus is data which is the primary enabler of any digital transformation program. New data is constantly created through the asset’s lifecycle, with new wells being drilled as the greenfield development progresses to maturity, producing assets. Erosion, corrosion, and flow assurance challenges resulting from declining pressures become a strong focus area as fields mature. Comprehensive well data becomes a critical requirement to drive production optimization and reduced well interventions.

As the density of measurement increases, the technological approach must minimize installation costs and ease of implementation. Emerson’s portfolio of non-intrusive wireless devices makes this achievable by removing cabling and trenching activities and adding required communication agility through the Wireless HART protocol. Emerson’s smart well monitoring comprises of all the measurements starting from downhole pressure and temperature, surface pressures, process temperature, volumetric flow, localized erosion, and corrosion, H2S gas detection, sand/solids detection, wellhead vibration with continuous, uninterrupted, and seamless data streaming possible with the wireless mesh network. Emerson’s location awareness solution can be added to the existing network providing live location tracking to ensure personnel safety in remote and unsafe assets.

Accurate and quick decision-making depends on access to relevant data and information. Big data often comes with challenges in contextualization and its distribution. Existing data sources need to be integrated, validated, cleaned, and restored as the first step with agility and infinite scalability. The contextualized data needs to process into actionable information and distributed to the right stakeholders. The actionable information requires authentication and is often supported by data-driven platforms utilizing machine learning and AI platforms for decision support. A step ahead is to provide predictive analytics such as failure prediction, forecasting production rates that can lay the foundation for autonomous operations. Emerson’s Optics Analytics platform is a single-point convergence of data integration (Data Lake), workflows, and intelligent, agnostic platforms, with enterprise-wide visualization, alarming, and relevant information distribution capabilities.

A better understanding of the upstream process and its interaction and effect on the midstream and downstream is achieved by adopting technologies such as Digital Twin. The solution can be customized to the individual, organizational processes and can accommodate changes and allow their testing in the process and infrastructure in real-time. It can radically accelerate the speed to action, improve operational clarity and resolution, and map responses on the asset performance. Emerson’s Digital Twin is a virtual platform integrating control and simulation that allows organizations to test any proposed adjustments before applying these changes on the actual field or plant. The capabilities of the Digital Twin extend beyond mere testing, and simulations are identified as rapidly adopted technology in the world.

Security Designs and Services

With an increasingly connected oil and gas industry, more security challenges arise specifically for cybersecurity. OT remains vulnerable due to their connectivity to L4 L5 if proper firewalls and security policies are not in place. Per the several surveys carried out, it is established that cybersecurity measures are not keeping up with the speed of digitalization. Another critical challenge is the ever-evolving nature of threats, their intentions, and resulting business risk. An effective way to deal with these threats is incorporating cybersecurity in the digital transformation strategy. First, a complete data flow needs to be mapped across the various assets, processing areas, control stations, and headquarters followed by security gaps assessment as a continuous process and develop networks that can withstand and deflect the attacks to the process safety. The selection of proper sensors complying with the industry cybersecurity policies is crucial. Assigning security goals to all the stakeholders involved and educating them on the best practices and security operations must happen continuously. Emerson offers cybersecurity services, including training, consultancy, and network designs, by eliminating the access and ways of unnecessary interactions, introducing isolations in networks for critical operations, revisiting the logics, and enhancing their security, devising effective alarm management strategies, and utilizing engineered solutions.

Emerson as a technology partner

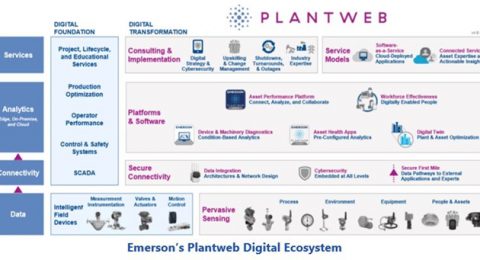

A successful Digital Transformation journey adopts the various cutting-edge technologies most befitting the current organizational readiness and the long-term goals with compliance to industrial security and cybersecurity standards. Since each organization will have a unique path, the potential technologies, including the devices, communication infrastructure, integration, and analytics platforms, should be scalable, agile, and vendor agnostic. Emerson offers a complete ecosystem (The Plantweb Digital Ecosystem) of the mentioned technologies coupled with the consultancy and training services that pledges the commitment as a technology partner in the ever-evolving journey of Digital Transformation.